Ateliers

The fabrication of 2 500 pièces per year can appear industrial.

But everything is artisanal, hand-made with the same gestures transmitted since many generations.

There is no engine to make a sofa or an armchair. Scissors, hammer or clamps, tools are the same as a yesteryear upholsterer.

Dimensions, comfort, finishes, each piece reflects the desires of the user.

We will count you how does work a workshop, and give you some manufacturing secrets ...

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon Crédits photo Nadia Mauléon

Crédits photo Nadia MauléonThe choice of your sofa consists of selection among 5 qualities and more than 120 colors of leather and around 200 references of fabrics, then the fabrication can start.

We need nearly twenty hours to produce a 3 seater-sofa Rivoli, best-seller of the timeless collection. And even more when the fabrication is custom-made.

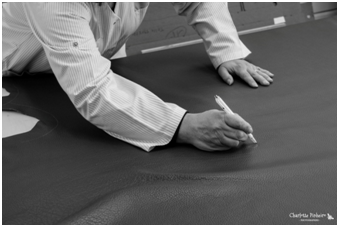

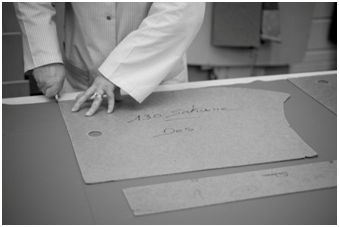

THE CUTTING WORKSHOP

In the atelier, we can hear scissors sharpening.

Four 5m² skins are spread on the table, all necessary for the confection of the sofa.

Each of them is carefully examined to find any scars or other insects bites and stings. The skin is stretched and scrutinized.

This is a crucial step.

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon

If the defect isn't discovered in time, it will be seen only after tapestry and there is no more painful than unhook or unravel a complete product.

We need 5 hours to place the 77 necessary pieces.

The priority is given to the most beautiful planks like the seats and the backs respecting the way and the uniformity of the grain.

We need 5 hours to place the 77 necessary pieces.

The priority is given to the most beautiful planks like the seats and the backs respecting the way and the uniformity of the grain.

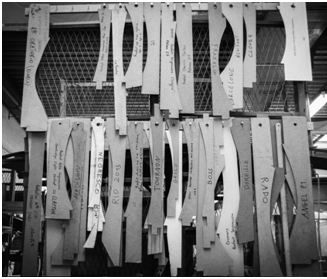

After many decades of activity, we can find all the jigs on the factory walls. Each dimension has its jig.

Only 60% of the skin area will be conserved.

Similarly, you can imagine a card of France in which we have to dispose big squares and rectangles avoiding some cities of departments. Moreover keep in mind that each leather skin is different from another because of its aspect and its dimensions.

Crédits photo Nadia Mauléon

Crédits photo Nadia MauléonNow you understand why only a few French manufacturers continue to work high-end full-grain leathers.

Our leathers, most of them full-grain and of a minimul thickness 1.4 mm, are tanned by French or Italian tanneries.

The most beautiful is the leather Toro which touch is unique, for a fabrication Neology certificated Origine France Garantie.

We only use the full-grain of the leather in our collections. This is the guarantee of a high-end and sustainable manufacture.

Sheep skins or Basane are prepared by a tanner in Mazamet (81).

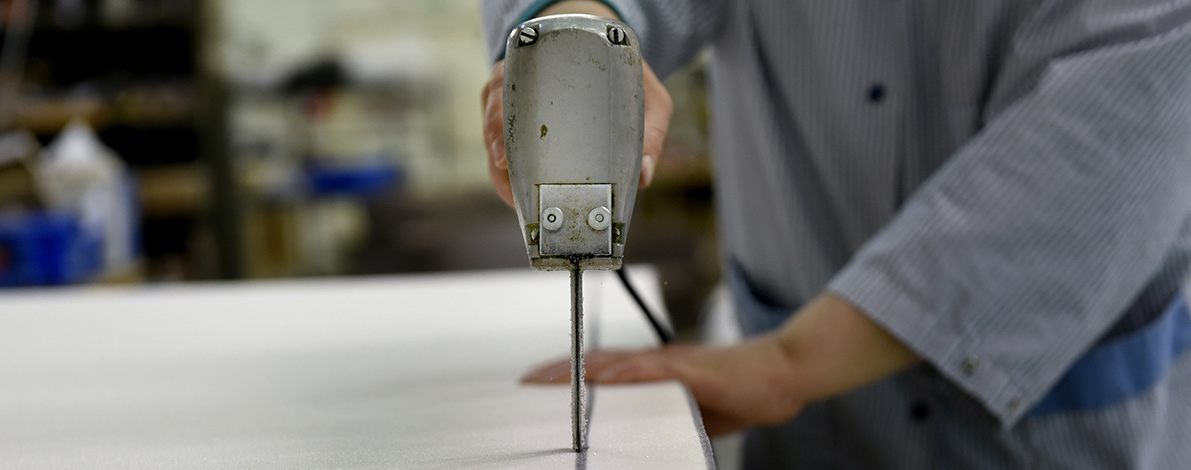

THE SEWING WORKSHOP

Once the 77 pieces of the Modèle Rivoli are identified and carefully categorized (cushions, ...) 6 hours are now necessary to assembly them.

The first step is the trimming.

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon Crédits photo Nadia Mauléon

Crédits photo Nadia MauléonThis is essential to facilitate the sewing of some parts of the leather, thinning out the edges of some or all pieces. This prevents an aggregate of 6,6 mm when you have to assembly 3 thicknesses of a full-grain leather. Even if our sewing machines could do it, the result wouldn't be aesthetic.

Nevertheless, this is a know-how which means a precise reduction of the thickness in order to maintain the leather resistance and to attain a clean final result.

The second step is the assembling.

Pieces are assembled in reversed with backgrounds, zips and others elements needed for tapestry.

This sensitive step doesn't allow any mistake because an unfortunate stitch can't be hidden and implies start all over again. That is why months, perhaps years are necessary to acquire experience between fabrics to leather sewing.

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon Crédits photo Nadia Mauléon

Crédits photo Nadia MauléonThe seamstress will be guided by 2 425 sewing stitch along the 194 linear meters of the sofa Rivoli.

The last step is the finishes.

Finishes are the next step after assembly, except for piping finishes. Selection of the thread tone on tone or contrasted, setting of the stitch width.

All sewing steps are attributed to the same artisan who can appropriate the final result.

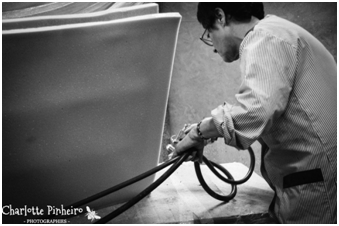

THE VARNISHing STEP

Wood and leathers are customized by the varnisher.

Massive beech or oak woodworks still are worked according the wood fiber. Then, to reach a perfect result, they are sanded, stained, abraded and varnished.

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon Crédits photo Nadia Mauléon

Crédits photo Nadia MauléonWe also work in this workshop the sheep leather wich is a natural full-grain leather used for the famous club armchair. The raw skins received are white and offer a waxed patina finish.

Cutting, sewing and tapestry, the armchair is entirely manufactured and is ready to return to the varnishing workshop, for various operations that we will keep secret.

The sheep leather is waxed with a brush, a cloth and a perfumed and colored wax.

And finally, the armchair is ready. The sheep leather will be polished during decades.

Crédits photo Marc Chaumeil

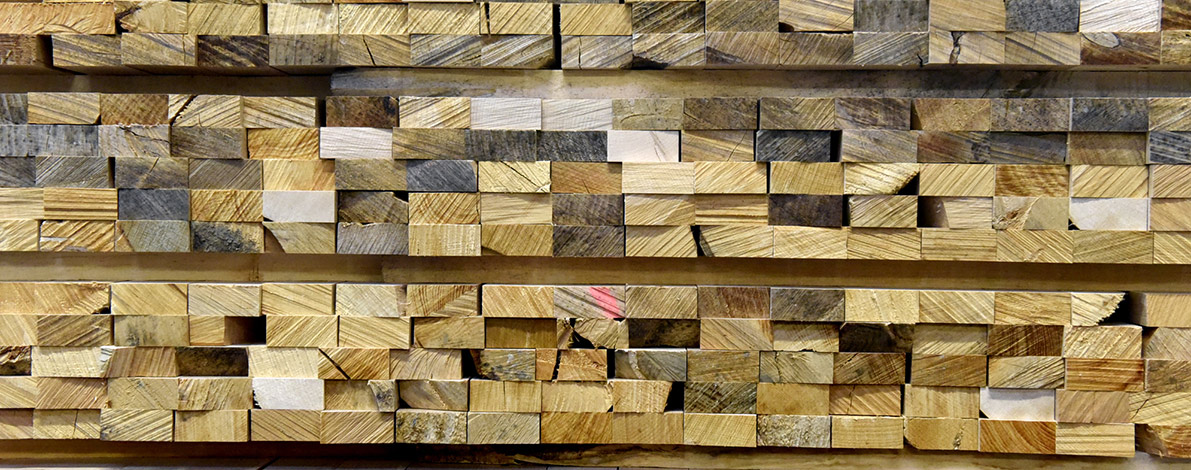

Crédits photo Marc ChaumeilTHE CARPENTRY WORKSHOP

Crédits photo Marc Chaumeil

Crédits photo Marc ChaumeilOur workshop is equipped with traditional and craft machines.

The massive beech comes from Puy-de-Dôme and guarantees a dairy use for more than 10 years.

The carpenter enumerates the different pieces listed by his sheet.

The final structure of a sofa is made by 26 pieces of 4 materials.

The carpenter sets some of pieces aside because they need additional cutout.

Like in the cutting workshop, the carpenter fabricates wooden jigs for each model of sofa.

Crédits photo Charlotte Pinheiro

Crédits photo Charlotte Pinheiro Crédits photo Nadia Mauléon

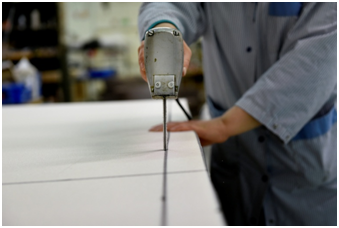

Crédits photo Nadia MauléonAfter tracing, the different elements are cutted by regular movements realizing a perfect manual cutting.

During the assembly, the craftsman begins a puzzle starting with the central part of the sofa : the frame.

Always assembly in beechwood, stapled and screwed to ensure rigidity.

All our frames, except for some shapes, are equipped with sinusoidal steel spring to avoid the webbing.

21 springs are necessary for the sofa Rivoli. They are connected between them by steel fasteners to guarantee an homogeneous and one-piece seat.

Then the frame of the seat, armrests and backrest, is joined to the chassis.

After 2 hours in the carpentry workshop, the frame of the sofa Rivoli is ready to be furnished.

Crédits photo Marc Chaumeil

Crédits photo Marc Chaumeil

The foam elements are assembled with a solvent-free adhesive in order to avoid hard parts under the coating.

For all areas which receive pressure like seats, backrests and armrests, high-resilience polyurethane foam is a must-have.

This is a characteristic of a high-end fabrication, the guarantee of excellent behaviour and comfort over time.

Wool and feathers can complete or furnish cushioning for a mellower comfort.

Wool duvets are made in France, in Haute-Vienne.

Feathers duvet are selected for an personalized assembly in the Vosges.

Crédits photo Marc Chaumeil

Crédits photo Marc ChaumeilTAPESTRY WORKSHOP

Crédits photo Marc Chaumeil

Crédits photo Marc ChaumeilThe framework and coating are finished. the sofa Rivoli is almost in your living room.

But before, the final step is to verify the accordance of the different workshops : the Tapestry.

The essential tool is the hands. And scissors, a stapler, and a hammer.

If upholstery techniques change, gestures stay.

The cover is setting up, stretched, stapled. Seams are positioned, adjusted, aligned.

Upholstery is a physical step. Some of models, the most sophisticated, are reserved to the most robust artisans and are alternated with other fabrications.

Crédits photo Nadia Mauléon

Crédits photo Nadia Mauléon Crédits photo Marc Chaumeil

Crédits photo Marc ChaumeilAfter 2 hours and hundred staples, this meticulous dressing shows a result.

Armrests, backrests and seats are generally the last pieces assembled.

Then, the upholstered ends with mechanisms, headrest, beds, backdrop and feet.

The made in France sofa is finished. Only the quality control is missing.

One person controls unitarily all fabrications. Aspect, compliance, finishes, the agreement is affixed.

The transporter is coming ... Just a few days to wait...

Crédits photo Marc Chaumeil

Crédits photo Marc Chaumeil